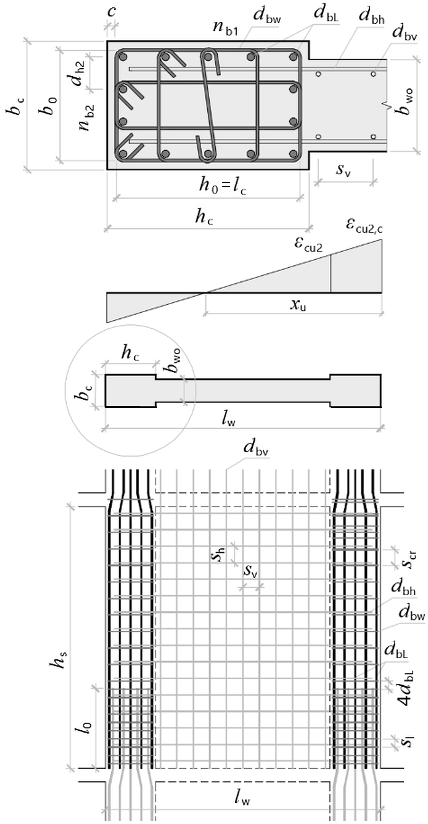

Shear wall dimensions

Length - lw = 4000 mm

Web thickness - bwo = 300 mm

Total height - hw = 19000 mm

Clear storey height - hs = 3820 mm

Number of storeys - ns = 6

Confined zone dimensions

bc = 300 mm, hc = 875 mm

Cross section area

Area of confined boundary element

Af = bc · hc = 300 · 875 = 262500 mm²

Web area

Aw = ( lw − 2 · hc ) · bwo = ( 4000 − 2 · 875 ) · 300 = 675000 mm²

Total area

Ac = Aw + 2 · Af = 675000 + 2 · 262500 = 1200000 mm²

Maximum seismic axial load - NEd = 2254 kN

Concrete [EN 1992-1-1, Table 3.1]

Characteristic compressive cylinder strength

fck = 25 MPa

Partial safety factor - γc = 1.5 , αct = 1 , αcc = 1

Mean value of axial tensile strength

fctm = 0.3 · fck23 = 0.3 · 2523 = 2.564964 MPa

Characteristic axial tensile strength

fctk,005 = 0.7 · fctm = 0.7 · 2.564964 = 1.795475 MPa

Design compressive cylinder strength

fcd = αcc · fckγc = 1 · 251.5 = 16.666667 MPa

Unconfined concrete ultimate strain

εcu2 = 0.0035

Ultimate compressive strain - εc2 = 0.002

Longitudinal reinforcement

Characteristic yield strength - fyk = 500 MPa

Selected steel class B500BPartial safety factor - γs = 1.15

Design yield strength - fyd = fykγs = 5001.15 = 434.782609 MPa

Modulus of elasticity - Es = 200000 MPa

Reinforcement for each confined boundary element

Bar diameter - dbL = 25 mm

[BS EN 1992-1-1, § 9.5.2 (1)/NA.1]

Minimum bar diameter - dbL,min = 12 mm

Bar count - nb = 13

Bar count along "h0" - nb1 = 6

Bar count along "b0" - nb2 = ceiling(nb2 − nb1 + 2) = ceiling(132 − 6 + 2) = 3

Reinforcement area

As1 = π · dbL24 = 3.141593 · 2524 = 490.873852 mm²

As = nb · As1 = 13 · 490.873852 = 6381.360078 mm²

Reinforcement ratio

ρL = AsAf = 6381.360078262500 = 0.02430994

[§ 5.4.3.4.2 (8)]

Design check: 0.005 ≤ ρL = 0.02430994 ≤ 0.04. The check is satisfied! ✓

Vertical web reinforcement

Bar diameter - dbv = 10 mm

Bar spacing - sv = 250 mm

[EN 1992-1-1, § 9.6.2 (3)]

Maximum bar spacing

sv,max = min ( 3 · bwo; 400 ) = min ( 3 · 300; 400 ) = 400 mm

Single bar area - Asv1 = π · dbv24 = 3.141593 · 1024 = 78.539816 mm²

Reinforcement ratio - ρv = 2 · Asv1sv · bwo = 2 · 78.539816250 · 300 = 0.002094395

[EN 1992-1-1, § 9.6.2 (1)]

Minimum reinforcement ratio - ρv,min = 0.002

[§ 5.4.3.4.2 (11)]

Minimum reinforcement ratio for zones with compressive strain > 0.002

ρv,min = 0.005

Horizontal web reinforcement

Bar diameter - dbh = 12 mm

Bar spacing - sh = 150 mm

[EN 1992-1-1, § 9.6.3 (2)]

Maximum bar spacing - sh,max = 400 mm

Single bar area - Ash1 = π · dbh24 = 3.141593 · 1224 = 113.097336 mm²

Reinforcement ratio - ρh = 2 · Ash1sh · bwo = 2 · 113.097336150 · 300 = 0.005026548

[EN 1992-1-1, § 9.6.3 (1)]

Minimum reinforcement ratio

ρh,min = max ( 0.25 · ρv; 0.001 ) = max ( 0.25 · 0.002094395; 0.001 ) = 0.001

Transverse reinforcement in confined boundary elements

Characteristic yield strength - fywk = 500 MPa

Design yield strength - fywd = fywkγs = 5001.15 = 434.782609 MPa

Concrete cover to hoops - c = 42 mm

Hoop diameter - dbw = 8 mm

[EN 1992-1-1, § 9.5.3 (1)]

Minimum diameter

dbw,min = max ( 6; 0.25 · dbL ) = max ( 6; 0.25 · 25 ) = 6.25 mm

Hoop diameter check:

dbw = 8 ≥ dbw,min = 6.25 mm. The check is satisfied! ✓

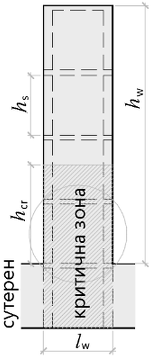

[§ 5.4.3.4.2 (1)]

Critical region height

hcr_ = max(lw; hw6) = max(4000; 190006) = 4000 mm

Must not be greater than

hcr,max = min ( 2 · lw; hs ) = min ( 2 · 4000; 3820 ) = 3820 mm, for number of storeys ns = 6 ≤ 6

hcr = min ( hcr_; hcr,max ) = min ( 4000; 3820 ) = 3820 mm

[§ 5.1.2 (1)]

Shear wall dimensions check

lwbwo = 4000300 = 13.333333 ≥ 4. The check is satisfied! ✓

[§ 5.4.1.2.3 (1)]

Minimum thickness - bw,min = max(150; hs20) = max(150; 382020) = 191 mm

bwo = 300 mm ≥ bw,min = 191 mm. The check is satisfied! ✓

[ § 5.4.3.4.2 (6)]

Confined boundary element length

lc = hc − ( dbw + 2 · c ) = 875 − ( 8 + 2 · 42 ) = 783 mm

Minimum confined boundary element length

lc,min = max ( 0.15 · lw; 1.5 · bc ) = max ( 0.15 · 4000; 1.5 · 300 ) = 600 mm

lc = 783 mm ≥ lc,min = 600 mm. The check is satisfied! ✓

[§ 5.4.3.4.2 (10)]

Minimum confined boundary element thickness

For lc = 783 mm ≤ max ( 2 · bc; 0.2 · lw ) = max ( 2 · 300; 0.2 · 4000 ) = 800 mm:

bc,min = max(hs15; 200) = max(382015; 200) = 254.666667 mm

bc = 300 mm ≥ bc,min = 254.666667 mm. The check is satisfied! ✓

[§ 5.4.3.4.1 (2)]

Check for normalized axial load

νd = NEdAc · fcd · 103 = 22541200000 · 16.666667 · 103 = 0.1127

νd = 0.1127 ≤ 0.4. The check is satisfied! ✓

Design anchorage length

η1 = 1 - when good conditions are provided

η2 = 1 - for dbL = 25 ≤ 32 mm

fctd = αct · fctk,005γc = 1 · 1.7954751.5 = 1.196983 MPa

[EN 1992-1-1, § 8.4.2 (2)]

fbd = 2.25 · η1 · η2 · fctd = 2.25 · 1 · 1 · 1.196983 = 2.693212 MPa

σsd = fyd = 434.782609 MPa

[EN 1992-1-1, § 8.4.3 (2)]

lb,rqd = dbL4 · σsdfbd = 254 · 434.7826092.693212 = 1008.977825 mm

[EN 1992-1-1, Table 8.2]

α1 = 1 , α2 = 1 , α3 = 1 , α5 = 1 , α6 = 1.5

[EN 1992-1-1, § 8.7.3 (1)]

l0_ = α1 · α2 · α3 · α5 · α6 · lb,rqd = 1 · 1 · 1 · 1 · 1.5 · 1008.977825 = 1513.466738 mm

l0,min = max ( 0.3 · α6 · lb,rqd; 15 · dbL; 200 ) = max ( 0.3 · 1.5 · 1008.977825; 15 · 25; 200 ) = 454.040021 mm

l0 = round ( max ( l0_; l0,min ) ) = round ( max ( 1513.466738; 454.040021 ) ) = 1513 mm

Confined core dimensions (between centerlines of hoops)

b0 = bc − ( dbw + 2 · c ) = 300 − ( 8 + 2 · 42 ) = 208 mm

h0 = hc − ( dbw + 2 · c ) = 875 − ( 8 + 2 · 42 ) = 783 mm

Maximum bar spacing

db1 = hc − 2 · ( dbw + c ) − dbLnb1 − 1 = 875 − 2 · ( 8 + 42 ) − 256 − 1 = 150 mm

db2 = bc − 2 · ( dbw + c ) − dbLnb2 − 1 = 300 − 2 · ( 8 + 42 ) − 253 − 1 = 87.5 mm

Maximum distance between consecutive longitudinal bars engaged by hoops

[§ 5.4.3.4.2 (9)]

dh,max = 200 mm

Distance between bars engaged by hoops

nh1 = max(floor(dh,maxdb1); 1) = max(floor(200150); 1) = 1

nh2 = max(floor(dh,maxdb2); 1) = max(floor(20087.5); 1) = 2

Distance between bars engaged by hoops

dh1 = nh1 · db1 = 1 · 150 = 150

dh2 = nh2 · db2 = 2 · 87.5 = 175

Distance between bars engaged by hoops

nh1 = round( ( nb1 − 1 ) · db1dh1) = round( ( 6 − 1 ) · 150150) = 5

nh2 = round( ( nb2 − 1 ) · db2dh2) = round( ( 3 − 1 ) · 87.5175) = 1

Hoop spacing in the critical region

[§ 5.4.3.4.2 (9)]

scr = min(b02; 8 · dbL; 175) = min(2082; 8 · 25; 175) = 104 mm

Hoop spacing in lap zone

[§ 5.6.3 (3), c)]

sl = min(100; bc4) = min(100; 3004) = 75 mm

Hoop spacing outside lap zone

[EN 1992-1-1, § 9.5.3 (3)]

s = min ( bc; 20 · dbL; 400 ) = min ( 300; 20 · 25; 400 ) = 300 mm

Transverse reinforcement in the lap zone

Required area of one leg

[§ 5.6.3 (4)]

Ast = sl · dbL50 · fydfywd = 75 · 2550 · 434.782609434.782609 = 37.5 mm²

Provided area of one leg

Asw1 = π · dbw24 = 3.141593 · 824 = 50.265482 mm²

Design check: Asw1 = 50.265482 mm² ≥ Ast = 37.5 mm². The check is satisfied! ✓

Check for bar diameters > 20 mm:

Number of legs in the outer 1/3 of lap zone

nw = round(2 · l03 · sl) = round(2 · 15133 · 75) = 13

Total area of legs in the outer 1/3 of lap zone

ΣAsw = Asw1 · nw = 50.265482 · 13 = 653.451272

[EN 1992-1-1 § 8.7.4.1 (3)]

Design check: ΣAsw = 653.451272 mm² ≥ As1 = 490.873852 mm²

An additional hoop is required for compressed bars

[EN 1992-1-1 § 8.7.4.2 (1)]

at 4 · dbL = 4 · 25 = 100 mm from the end of the lap zone.

Detailing for local ductility in the critical region

Total length of confining links

Σli = ( nh1 + 1 ) · b0 + ( nh2 + 1 ) · h0 = ( 5 + 1 ) · 208 + ( 1 + 1 ) · 783 = 2814

Mechanical volumetric ratio of confining hoops within the critical region

ωd = Asw1 · Σlib0 · h0 · scr · fywdfcd = 50.265482 · 2814208 · 783 · 104 · 434.78260916.666667 = 0.2178507

[§ 5.4.3.2.2 (8)]

The minimum value is 0.08.

Design check: ωd = 0.2178507 ≥ 0.08 = 0.08 . The check is satisfied! ✓

Sum of the squares of the distances between consecutive engaged bars

Σb2i = 2 · ( nh1 · dh12 + nh2 · dh22 ) = 2 · ( 5 · 1502 + 1 · 1752 ) = 286250

Confinement effectiveness factors for bars and links

αn = 1 − Σb2i6 · b0 · h0 = 1 − 2862506 · 208 · 783 = 0.7070664

αs = (1 − scr2 · b0) · (1 − scr2 · h0) = (1 − 1042 · 208) · (1 − 1042 · 783) = 0.7001916

α = αn · αs = 0.7070664 · 0.7001916 = 0.495082

Analysis results

Fundamental period of first vibration mode - T1 = 0.6795 s

Upper limit period of constant spectral acceleration - TC = 0.4 s

Basic behavior factor value - q0 = 3

Design bending moment - MEd = 9591 kNm

Bending moment capacity - MRd = 13268 kNm

(The above values refer to the section above the base)

Curvature ductility factor

[§ 5.2.3.4 (3)]

μΦ = 2 · q0 · MEdMRd − 1 = 2 · 3 · 959113268 − 1 = 3.337202 - for T1 ≥ TC

[§ 5.2.3.4 (4)]

For steel class B, ductility factor is increased by 50% - μΦ = 5.005803

Design value of steel yield strain - εsy,d = fydEs = 434.782609200000 = 0.002173913

Mechanical ratio of vertical web reinforcement

ωv = ρv · fydfcd = 0.002094395 · 434.78260916.666667 = 0.05463639

[§ 5.4.3.4.2 (4)]

Design check: αωd ≥ αωd_min = 30·μΦ·(νd + ωv )·εsy_d·bc/b0 – 0.035

αωd = α · ωd = 0.495082 · 0.2178507 = 0.1078539

αωd,min = 30 · μΦ · ( νd + ωv ) · εsy,d · bcb0 − 0.035 = 30 · 5.005803 · ( 0.1127 + 0.05463639 ) · 0.002173913 · 300208 − 0.035 = 0.04379262

The required curvature ductility is provided: αωd = 0.1078539 ≥ αωd,min = 0.04379262 . ✓

Ultimate strain of confined concrete

εcu2,c = 0.0035 + 0.1 · αωd = 0.0035 + 0.1 · 0.1078539 = 0.01428539

Neutral axis depth at ultimate curvature

xu = ( νd + ωv ) · lw · bcb0 = ( 0.1127 + 0.05463639 ) · 4000 · 300208 = 965.402273 mm

Confined boundary element length

lc,req = xu · (1 − εcu2εcu2,c) = 965.402273 · (1 − 0.00350.01428539) = 728.873416 mm

Design check: lc = 783 mm ≥ lc,req = 728.873416 mm. The check is satisfied! ✓

NOTE: All references are according to EN 1998-1, unless noted otherwise.